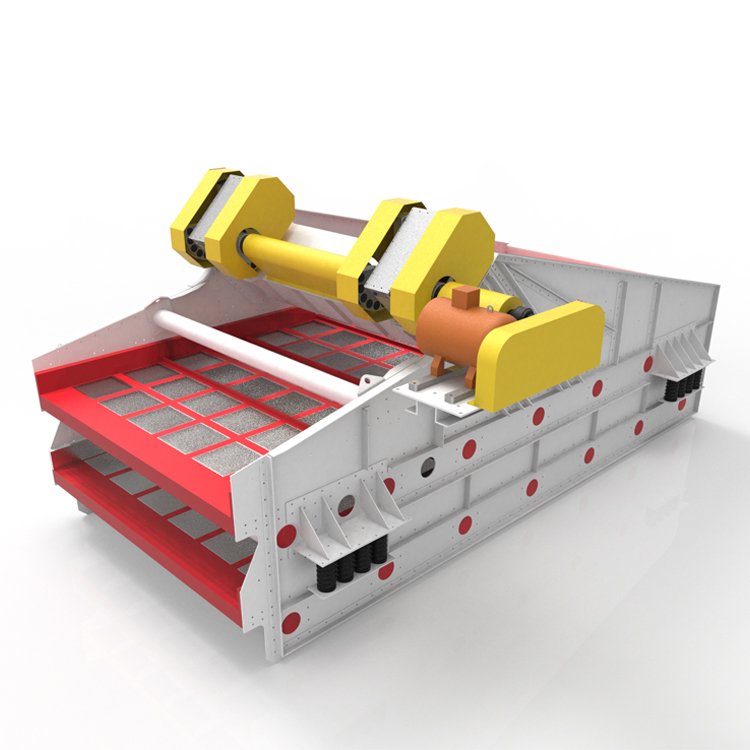

Mining vibrating screen is a kind of mechanical equipment specially used in the mining industry to screen and grade minerals. It separates mineral particles of different sizes by mechanical vibration, so as to achieve the purpose of purification, classification and grading.

Several types of mining vibration screening

1. Drum sieve

Working principle: The screen box moves in a circle around the central axis, and the unloaded material is graded through the screen under the combined action of centrifugal force and vibration.

Application: Mainly used for ore screening to separate useful minerals from gangue in the ore.

Working principle: The screen box reciprocates horizontally, and the material slides and jumps on the screen surface to achieve screening.

Application: Commonly used for mineral concentrate screening, desludging, etc.

3. Tilt vibrating screen

Working principle: The screen box is tilted at a certain angle, and the material flows along the screen surface and passes through the screen under the action of gravity and vibration.

Application: Commonly used for wet screening and clay screening.

Working principle: The traction screen generates high-frequency vibration through the motor drive, which makes the screen box vibrate up and down, left and right and tilted. The filler moves forward along the box screen surface under the action of vibration. The solid particles in the warehouse are intercepted by the screen, while the water is interrupted by the screen.

Application: Mainly used to process materials with high water content such as coal, ore, sand, construction slag, chemical raw materials, etc.

Selection suggestions for mining vibrating screens

When choosing a suitable mining vibrating screen, you can consider the following selection suggestions:

Processing capacity requirements: First, consider the amount of granular material that your production line needs to process per hour, and choose a vibrating screen with processing capacity that meets the requirements.

Screening particle size: According to your product requirements, determine the required screening particle size range and select a vibrating screen that can meet the particle size requirements.

Material properties: Consider the characteristics of the material to be screened, such as viscosity, humidity, etc., and choose a vibrating screen suitable for handling these characteristics.

Equipment size: According to the space and layout of your production site, choose a vibrating screen of appropriate size to ensure that the equipment is easy to install and operate.

Vibration mode: According to the characteristics of the material and screening requirements, select a suitable vibration mode, such as linear vibration, circular vibration, etc.

Screen type: According to the characteristics of the granular material and screening requirements, select a suitable screen type, such as metal screen, rubber screen, etc.

Mining vibrating screen, as an effective screening equipment, plays an important role in the mining industry. With the continuous advancement of technology, the performance of mining vibrating screens will continue to improve, providing greater support for the development of the mining industry.