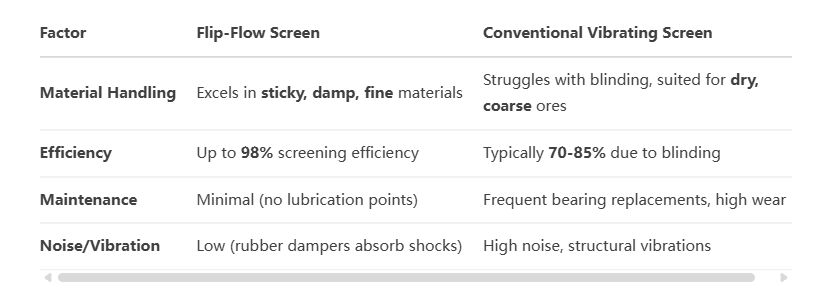

Are you struggling with screen blinding, high maintenance costs, or inefficient separation of fine and sticky materials? Meet the Flip-Flow Screen – a game-changer in mineral processing. Let’s dive into why this technology is outperforming traditional vibrating screens and how it can transform your operations.

Key Advantages of Flip-Flow Screens

Eliminate Screen Blinding

The elastic polyurethane screen panels stretch and relax dynamically, preventing material buildup in apertures – perfect for wet, sticky, or fibrous ores (e.g., coal, iron ore, rare earths).

Superior Fine Particle Separation

Achieve precise screening down to 0.1mm, ideal for recovering high-value fines (e.g., lithium, copper concentrates).

Low Energy, High Efficiency

The dual-mass vibration system reduces energy consumption by 30-50% compared to conventional screens.

Durability & Low Maintenance

Robust rubber damping blocks and anti-abrasion screen decks extend service life, slashing downtime.

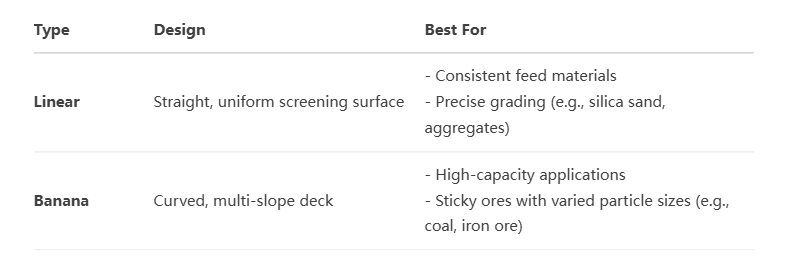

Linear vs. Banana Flip-Flow Screens: Which to Choose?

Flip-Flow vs. Traditional Screens: The Ultimate Showdown

Applications Making a Difference

Coal Washing: Efficient dewatering and desliming of high-moisture coal.

Metallic Ores: Recovery of fine copper, gold, or lithium particles from tailings.

Recycling: Separation of plastics, metals, and e-waste fragments.

Final Thought

In an era where mineral complexity and sustainability matter, flip-flow screens are not just an upgrade – they’re a necessity. Whether you’re optimizing a greenfield project or retrofitting an existing plant, this technology delivers lower OPEX, higher yield, and greener operations.

Ready to upgrade your screening process? Let’s connect and explore how flip-flow screens can solve your toughest material challenges!