Ore processing is a critical stage in the mining lifecycle, where raw ore is transformed into valuable concentrates ready for further processing and refinement. Traditional methods of ore processing often rely on gravity-based separation techniques, which can be inefficient and labor-intensive. However, the advent of centrifugal technology has ushered in a new era of efficiency and productivity, offering a highly effective solution for ore processing challenges.

Enhanced Separation Efficiency:

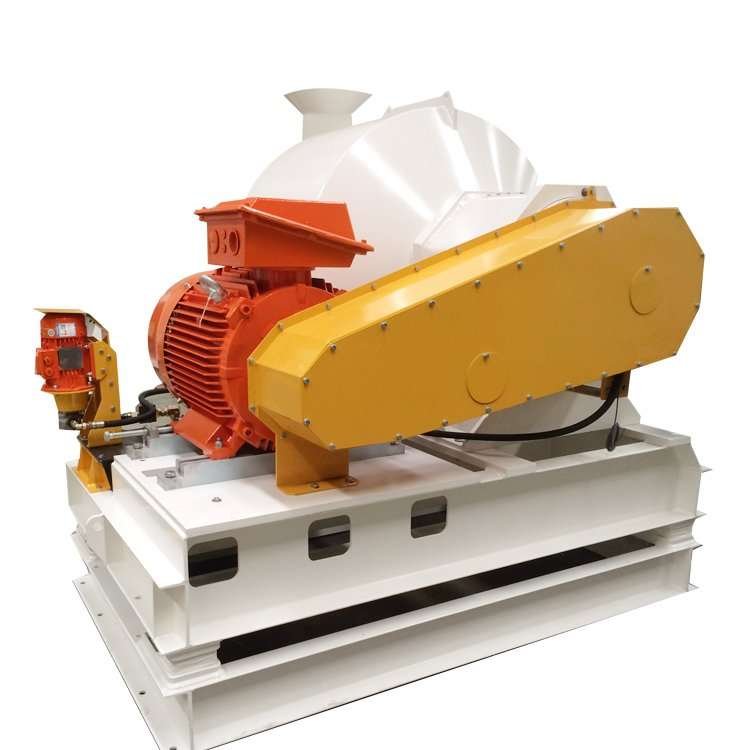

Centrifuges play a central role in ore processing by leveraging centrifugal force to separate particles based on their size, density, and other physical properties. Unlike traditional gravity-based methods, centrifugal separation offers superior efficiency and precision, allowing for the extraction of valuable minerals with high purity and yield. This enhanced separation efficiency minimizes waste and maximizes resource utilization, driving profitability and sustainability in mining operations.

Versatility Across Applications:

One of the key strengths of centrifuges lies in their versatility and adaptability to a wide range of ore processing applications. From coal and iron ore to precious metals and rare earth elements, centrifuges can effectively process a diverse array of ore types, making them indispensable assets for mining companies operating in various sectors. Whether it’s concentrating ore slurries, dewatering tailings, or recovering fine particles, centrifuges offer a versatile solution that meets the evolving needs of the mining industry.

Optimized Recovery and Concentration:

Centrifuges excel in optimizing mineral recovery and concentration, enabling mining companies to extract maximum value from their ore deposits. By efficiently separating valuable minerals from gangue and other impurities, centrifuges facilitate the production of high-grade concentrates that command premium prices in the market. This optimized recovery and concentration process enhance the overall profitability and competitiveness of mining operations, driving sustainable growth and success.

Reduced Environmental Impact:

In addition to their economic benefits, centrifuges also contribute to reducing the environmental impact of mining operations. By efficiently recovering valuable minerals and minimizing waste generation, centrifuges help reduce the footprint of mining activities and mitigate environmental risks associated with tailings disposal. Furthermore, the use of centrifuges in ore processing can lead to lower energy consumption and water usage compared to traditional methods, further enhancing their environmental sustainability credentials.